The honeycomb structure is made by honeycomb core and two skins bonded on the top and bottom of the core. It is widely used in the fields of aviation, aerospace, transportation, and building industry. As it is often susceptible to defects especially debonding, for decades, radiographic testing, ultrasonic C-scan, acoustic impedance testing, thermography, acoustic emission, shearography, guided wave testing et.al have been introduced to inspect the defect in honeycomb structure. However, the efficiency, sensitivity, and feasibility can hardly be achieved simultaneously for now available methods.

Researchers from the Institute of Acoustics of the Chinese Academy of Sciences (IACAS) proposed a novel nondestructive testing method by taking advantage of band gap characteristics in honeycomb structure due to its space periodicity. Meanwhile, researchers developed the corresponding devices for testing and scanning, and successfully and rapidly detected and located the debonding defects in honeycomb strcucture.

The research was published online in Mechanical Systems and Signal Processing.

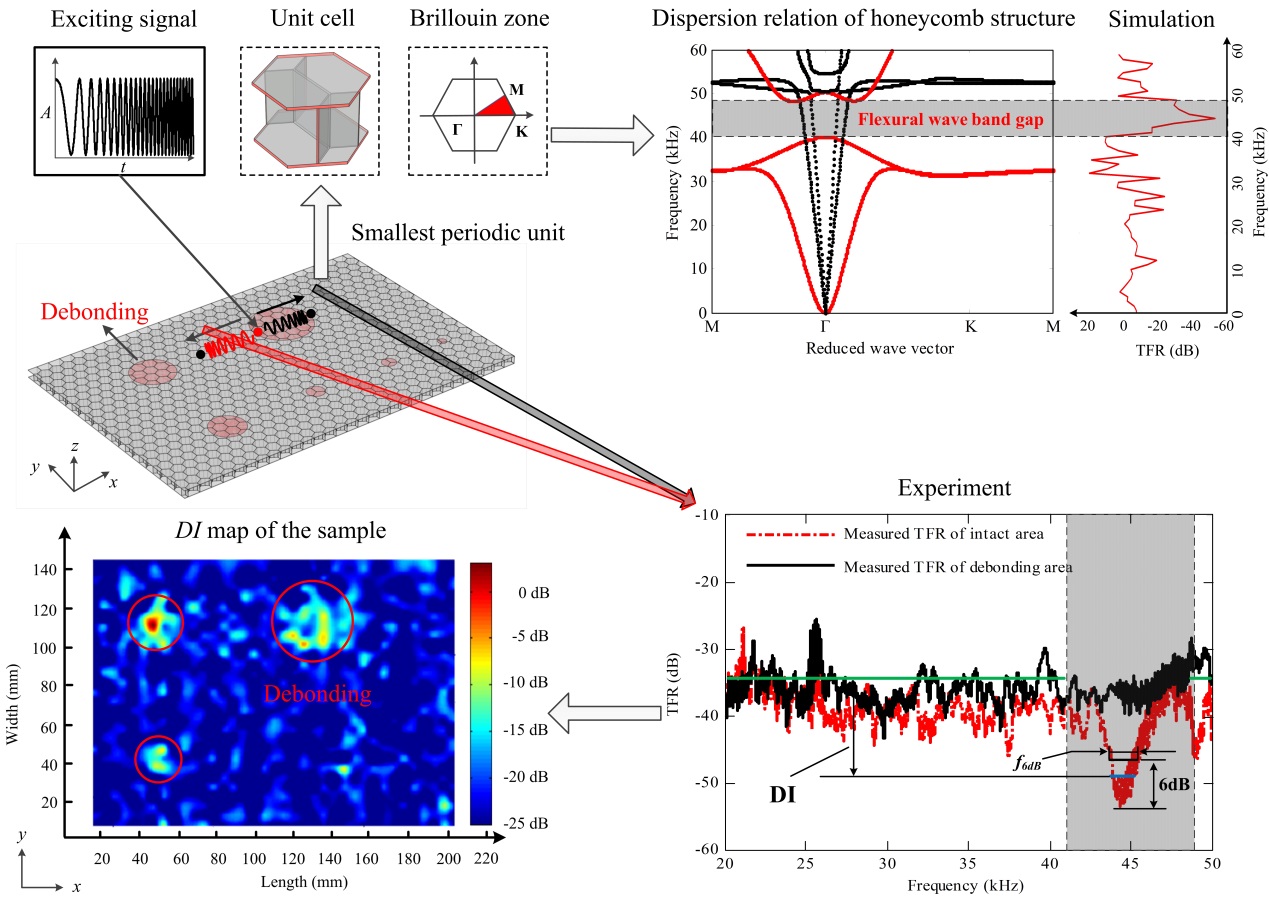

Researchers calculated and analyzed the dispersion relation of the brazed honeycomb structure sample. It is exhibited that there is a flexural wave band gap in the frequency range of 41 kHz ~ 48 kHz for the honeycomb structure. This gap is caused by the interaction between the local resonant vibration of the skins and the bending vibration of the structure, and it disappears in the debonding area. A device for this method was constructed and the flexural wave transmission frequency response (TFR) was measured on intact area and debonding area, respectively. The results verified the existence of the band gap in the intact area, and the gap disappeared in the debonding area. A damage index was defined, and the sample was scanned by this method. The result image showed that the method proposed in this paper can successfully detect and locate the debonding defects whose size is no smaller than 20 mm in our condition.

Figure 1. A novel method for debonding defects in honeycomb structure based on acoustic characteristic analysis due to its space periodicity. (Image by IACAS)

The proposed method could rapidly detect and locate the debonding defects with high sensitivity. Additionally, the method did not require sophisticated equipment and complex signal processing procedure. Therefore, it is suggested that the method proposed in this work is more suitable for field test and can meet the industrial detection requirements of honeycomb structure.

The proposed method could rapidly detect and locate the debonding defects with high sensitivity. Additionally, the method did not require sophisticated equipment and complex signal processing procedure. Therefore, it is suggested that the method proposed in this work is more suitable for field test and can meet the industrial detection requirements of honeycomb structure. Besides the honeycomb structures, this method is also applicable to other structures with space periodicity, such as grid structures, corrugated tubes and railway tracks.

Reference:

Yuan Y, Liu B, Jia H, et al. A novel nondestructive testing method for honeycomb structure using acoustic band gap. Mechanical Systems and Signal Processing, 2023,188:110053. DOI: 10.1016/j.ymssp.2022.110053

Contact:

ZHOU Wenjia

Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: media@mail.ioa.ac.cn