The surface acoustic wave (SAW) sensing technology features a wireless and passive measurement. It provides an effective solution of on-line health monitoring towards equipment at high temperature, high pressure and unattended environments in field of aerospace, ocean, power grid, rail transit and industry.

Based on the long-term basic research on SAW technology, researchers from the Institute of Acoustics of the Chinese Academic of Sciences (IACAS) successfully proposed and developed a wireless and passive temperature-compensated SAW strain sensor for on-line health monitoring of key components of helicopter.

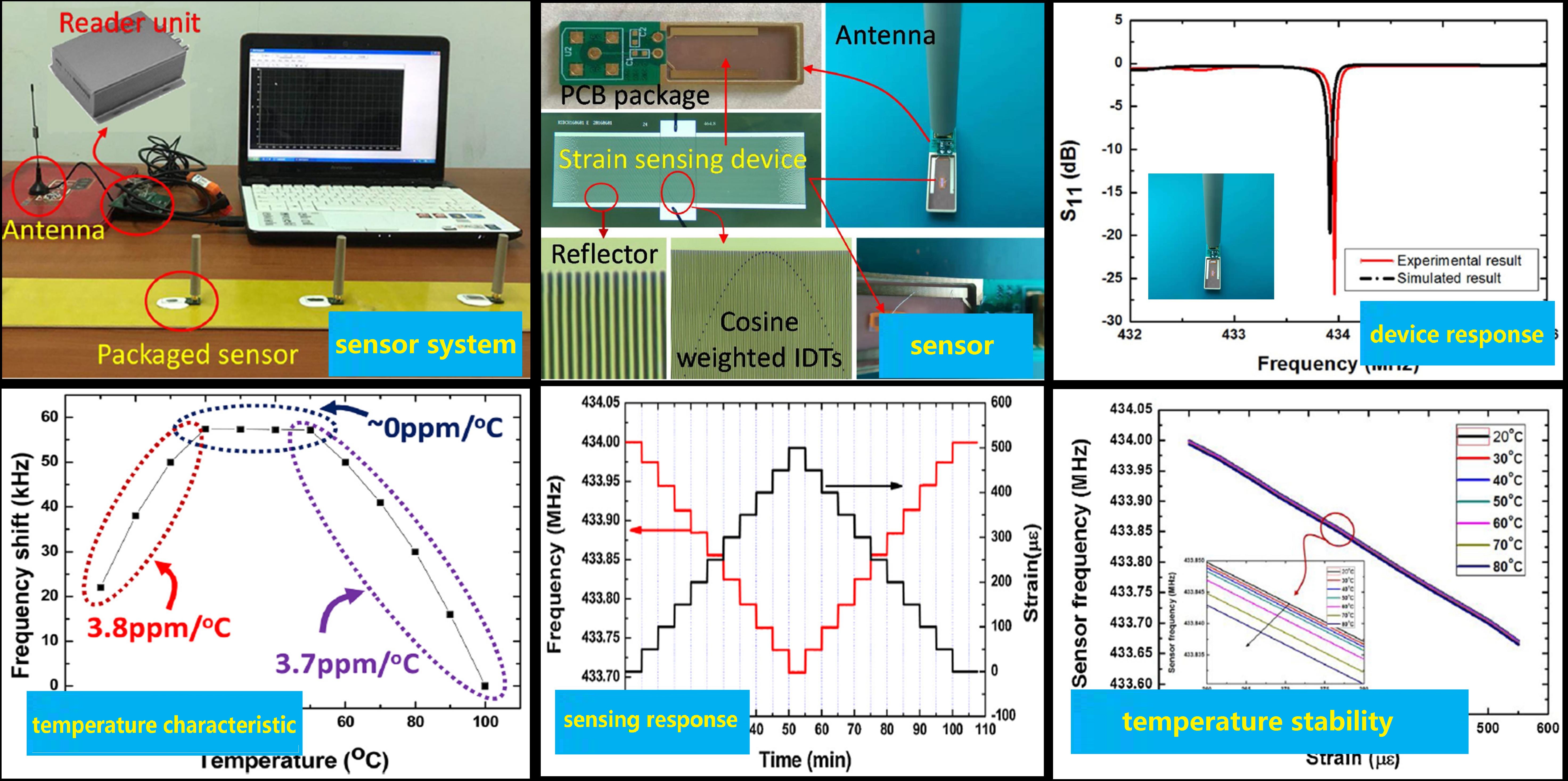

Researchers explored a Y-cut 35oX quartz piezoelectric substrate with excellent temperature stability. They optimized the sensing chip patterned by one-port resonator configuration with large quality factor (Q-value >12000). Then, they built a wireless and passive SAW strain sensing system by referring to the radio frequency (RF) reading unit and packaging design.

The developed sensor was characterized by constructing the test platform. The test results of the proposed sensor system showed that its high strain sensitivity was 598 Hz/με, lower temperature drift was less than 1.8% (<80oC) and readout distance was 2m.

The study, published in Sensors and Actuators A: Physical, was supported by the National Natural Science Foundation of China.

Wireless and passive temperature-compensated SAW strain sensor (Image by IACAS)

Reference:

WANG Wen, XUE Xufeng, FAN Shuyao, LIU Mengwei, LIANG Yong, LU Minghui. Development of a wireless and passive temperature-compensated SAW strain sensor. Sensors and Actuators A: Physical, Chemical, 2020, 308, 112015. DOI: 10.1016/j.sna.2020.112015

Contact:

ZHOU Wenjia

Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: media@mail.ioa.ac.cn