Due to excellent physicochemical properties, hydrogen appears to be an efficient source of energy for powering devices such as hydrogen engines. However, particular care should be dedicated to control gaseous leaks close to facilities using this resource because of the explosiveness nature of the hydrogen in air. The most effective way to respond to such an issue is the early detection and monitoring of the hydrogen leakage. Obviously, fast response and high sensitivity are the essential requirements for the hydrogen sensor.

Among the available approaches for sensing hydrogen, surface acoustic wave (SAW) gas sensors attracts increasing interest because of their unique features such as small size, low cost, satisfied stability and remarkable sensitivity. Although plenty of meaningful results have been achieved from the proposed hydrogen gas sensing device based on SAW, the response and recovery time of the proposed prototypes are still difficult to meet requirements.

To solve this issue, researchers from the Institute of Acoustics of the Chinese Academy of Sciences (IACAS) along with researchers from Nankai University proposed and developed a new configuration of SAW hydrogen sensor built by the Pd/Cu nanowires. Larger surface-to-volume of the Pd/Cu NWs contributed to improve the response speed and sensitivity.

The related research results were recently published in Sensors and Actuator B.

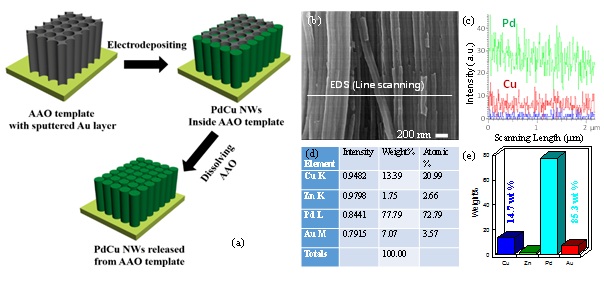

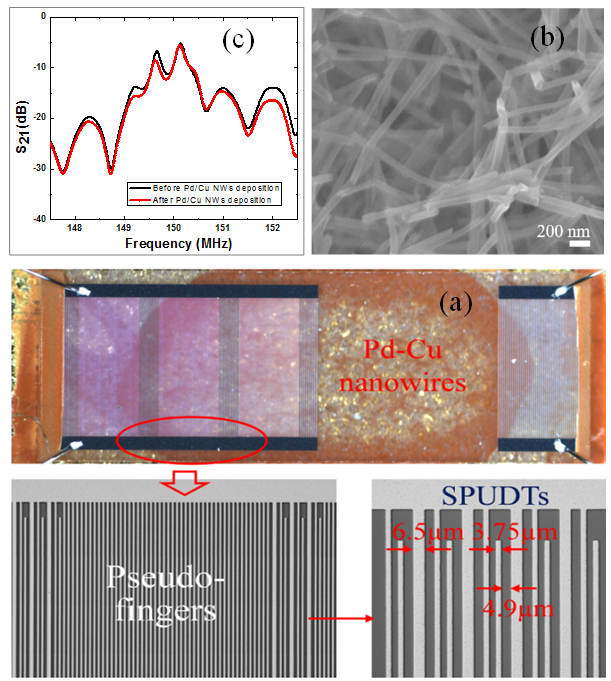

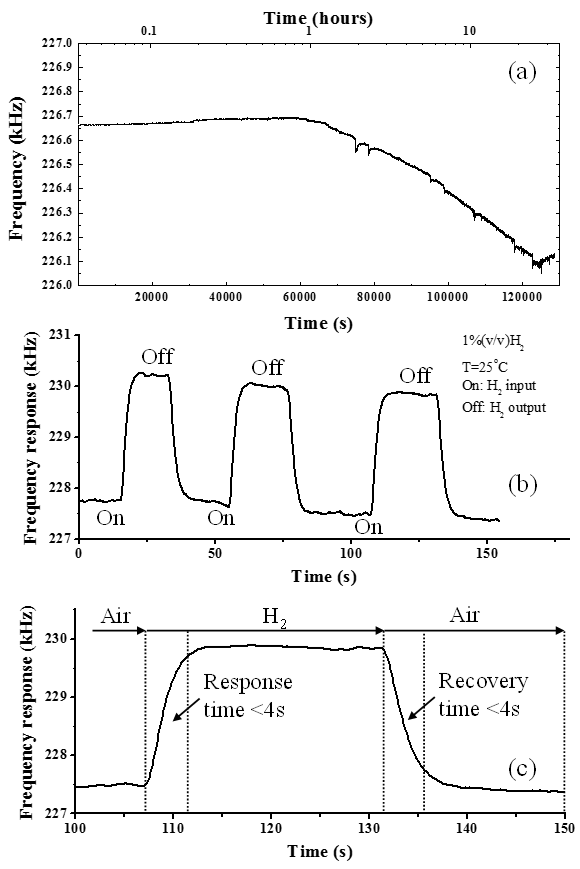

Researchers photolithographically fabricated a 150 MHz SAW device with delay line pattern on 128o YX LiNbO3 substrate. The Pd/Cu NWs synthesized by optimized electrochemical deposition (Fig. 1) were dissolved in ethanol and deposited onto the SAW device surface by dropping method to build the SAW hydrogen sensors (Fig. 2). The prepared SAW sensors were characterized by using the differential oscillation loop experimentally, excellent repeatability, fast response and recovery within 4s, low detection limit of 7 ppm. A sensitivity of 1.5 kHz/% were achieved at room temperature (25 oC).

Additionally, the dominant response mechanism of the proposed hydrogen sensor was determined as the acoustoelectric coupling effect by investigating the sensing device with and without intervening Al thin-film. From these results, we suggest that the proposed Pd/Cu NWs coated SAW sensor is very promising for hydrogen detection application.

Figure 1 Synthetic process and characterization of Pd/Cu nanowires(Image by IOA)

Figure 2 The proposed Pd/Cu NWs coated SAW sensing device(Image by IOA)

Figure 3 Response characteristics of the proposed sensing device(Image by IOA)

Reference:

WANG Wen, LIU Xueli, MEI Shenchao, JIA Yana, LIU Mengwei, XUE Xufeng, YANG Dachi, “Development of A Pd/Cu Nanowires Coated SAW Hydrogen Gas Sensor with Fast Response and Recovery”, Sensors and Actuator B, 2019, 287, 157-164. DOI: 10.1016/j.snb.2019.02.047

Contact:

ZHOU Wenjia

Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: media@mail.ioa.ac.cn