After nearly three years of technical exploration, researchers at the Institute of Acoustics (IOA) of the Chinese Academy of Sciences proposed a novel surface acoustic waves (SAW) current sensor with high sensitivity, low hysteresis error, and good stability.

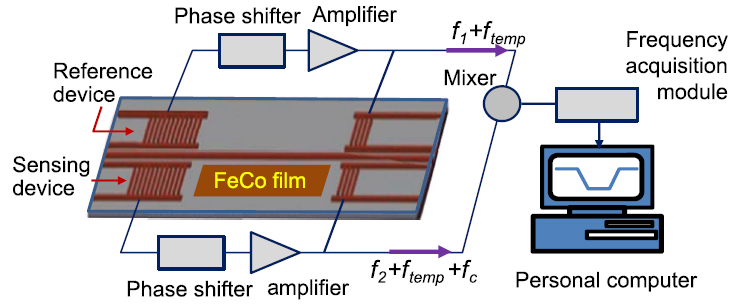

The SAW current sensor is composed of SAW dual-channel delay liner differential oscillator, with FeCo film deposited on one of the SAW propagation path. Due to the magnetostrictive effect, the FeCo film produces magnetostrictive strain under the magnetic field generated by the applied current. The thickness, density, and Young’s modulus of the FeCo film change accordingly, and then the SAW propagation characteristic can be modulated in the form of a linear SAW velocity shift. Obtained by the frequency acquisition module (FAM), the corresponding change in differential oscillation frequency is used to evaluate the tested current.

Fig.1 Scheme and working principle of the SAW current sensor (Image by IOA)

The SAW current sensor has the characteristics of fast response, simple structure, strong anti-interference ability, long service life and small size. In particular, it can realize wireless passive current detection means, which greatly improves system security, and can be applied in smart grid line testing and power relay protecting in industrial automation.

As outcome of “Research on Key Technologies for New Sensing and Energy Storage Cells for Grid Applications” project, the research was funded by State Grid Corporation.