As a typical passive sound absorber, the acoustical structure composed of a porous material with a perforated facing has been widely applied in noise control engineering, such as silencer.

Many papers about its sound absorption characteristics under linear condition have been published before, while there is little research under high sound pressure levels (SPLs), because both the perforated panel (PP) and the porous material behave nonlinearly and it is more complicated to construct a theoretical model.

Researcher PENG Feng from the Institute of Acoustics (IOA) of the Chinese Academy of Sciences investigated this problem and proposed a semi-empirical model to predict the sound absorption of an acoustical absorber consisting of a porous material with a perforated facing at high sound pressure levels.

The research was published online in Journal of Sound and Vibration on April 7.

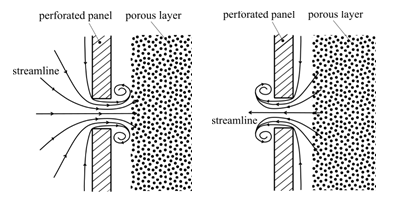

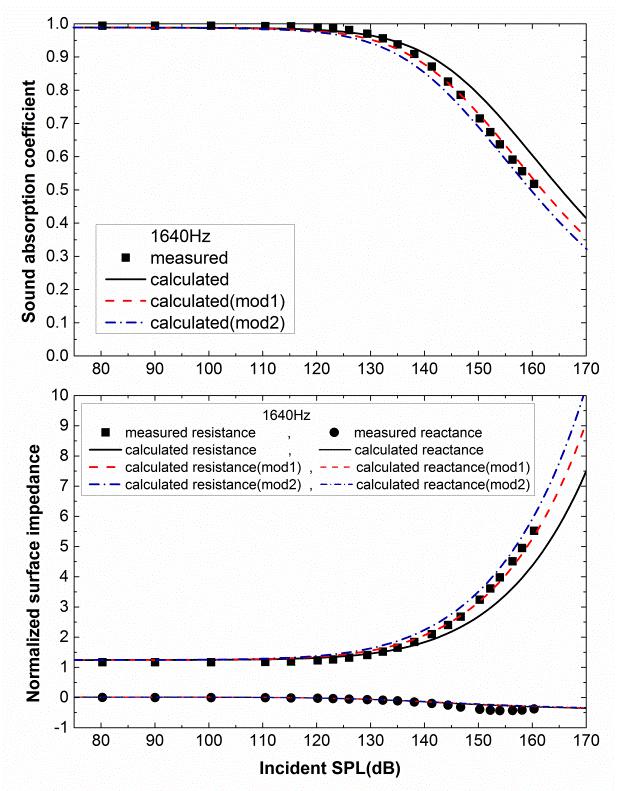

Researcher took the nonlinearity of the perforated facing and the porous material, and the interference between them (Figure 1) into account when building the prediction model. Test results agreed well with the corresponding theoretical predictions, thus validating the model. One of the comparison cases is shown in Figure 2.

Figure1. Schematic illustration of the typical flow patterns of the acoustical structure at high sound pressure excitation. (Image by IOA)

Figure2. Comparison of the measured and predicted results of sound absorption of an acoustical structure. (Image by IOA)

Based on detailed analysis and discussion on the nonlinear sound absorption characteristics of the acoustical structure, researcher proposed two guidelines for improving its sound absorptive performance under high SPLs. The first is to design an acoustical unit whose absorption is relatively weakly dependent on the incident SPL; the second is place the acoustical unit in the state of under-resistance under the linear condition, and design the critical SPL to be near the specific SPL of the working condition.

The developed model and proposed guidelines have potential values in design of this type of absorber in some intense sound environments.

Reference:

PENG Feng. Sound Absorption of a Porous Material with a Perforated Facing at High Sound Pressure Levels. Journal of Sound and Vibration (Volume 425, 7 July 2018, Pages 1-20). DOI: 10.1016/j.jsv.2018.03.028

Contact:

WANG Rongquan

Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: media@mail.ioa.ac.cn