Applications of ultrasonic cavitation span many industrial sectors, from sonochemistry, through ultrasonic cleaning, ultrasonic lithotripsy, sonoporation, emulsification, sludge reduction, nanoparticle preparation and wastewater treatment, to ultrasonic cell disruption.

The details of cavitation structure are usually difficult to be observed and unsuitable for stability research because of its three dimensional shape and complex mass transfer process with surroundings. To overcome the difficulty, the cavitation structures in thin liquid layers (between two parallel solid walls) are used to investigate the stability of cavitation structures, because the quasi-2D structure can be clearly photographed and easily controlled.

To investigate the stability of cavitation structures, recently, researchers WU Pengfei, BAI Lixin, LIN Weijun et al. from the Institute of Acoustics of the Chinese Academy of Sciences research the inception and evolution of acoustic cavitation structures in thin liquid layers under different conditions and perturbations experimentally with high speed photography. The stability and characterization of cavitation structures are quantified by image analysis methods.

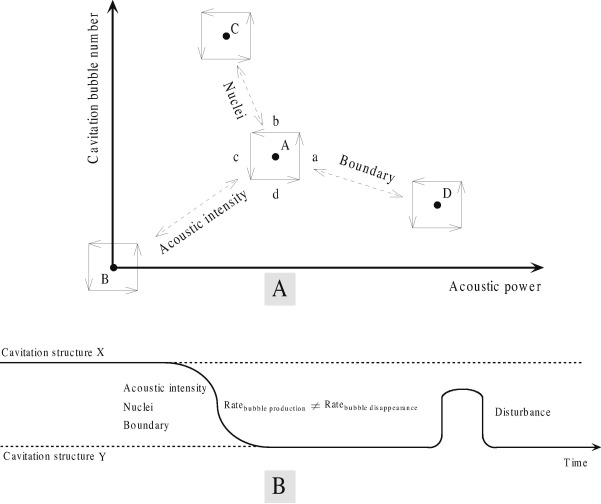

The transformation and stability mechanism of cavitation structures can be found in Fig.1. The horizontal coordinate represents the acoustic power penetrating the cavitation cloud. The longitudinal coordinate represents the total number of cavitation bubbles in the cavitation cloud.

When experimental conditions have a perturbation, the rate of bubble production and disappearance loses balance for a moment, and then recover balance under a negative feedback mechanism, as shown the arrows surrounding steady-state A in the Fig.1A.

If the rate of bubble production is not equal to the rate of bubble disappearance, and the number of cavitation bubbles changes, cavitation bubble cloud evolve into another kind of cavitation structure.

The steady-state A, B, C and D in Fig.1A are four steady states of cavitation structures under different conditions. If the rate of bubble production and disappearance keeps balance, the total number of cavitation bubble remains unchanged.

When the experimental conditions are altered, the rate of bubble production and disappearance loses balance, the cavitation structures vary correspondingly, and the variation is relative reversible. The increase and decrease of bubble production and disappearance rate are related to the changes of acoustic intensity, bubble nuclei and boundary.

Researchers find that the cavitation structures in the thin liquid layers have stability against transient perturbation to keep and recover to its original shape and bubble numbers. When the experimental conditions change (for example, acoustic intensity, cavitation nuclei and boundary), the cavitation structures will vary correspondingly and then remain stable over time.

There exist two processes acting simultaneously in the cavitation bubble cloud evolution, one "bubble production" and the other "bubble disappearance". A competition and dynamic balance of the two processes with a negative feedback mechanism have been proposed to explain the stability of cavitation structures and their transformation.

Funding for this research came from the National Natural Science Foundation of China (No. 11674350) (No.11174315) (No.51435004).

Fig.1 Schematic diagram of transformation and stabilization of cavitation structures. A, B, C, D, X and Y represent steady states of cavitation structures; a,b,c and d represent four processes which form a closed loop negative feedback (Image by BAI Lixin et al.)

Reference:

WU Pengfei , BAI Lixin, LIN Weijun, YAN Jiuchun. Stability of Cavitation Structures in a Thin Liquid Layer. Ultrasonics Sonochemistry (Volume 38, September 2017, Pages 75–83). DOI:10.1016/j.ultsonch.2017.03.002

Contact:

BAI Lixin

Research Center for Ultrasonics and Technologies, Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: blx@mail.ioa.ac.cn