Due to the shortage of the fossil fuel and with the increasing demand for it, heavy crude oil and ultra heavy crude oil whose density are less than 10API and 20API respectively are getting more and more attention in the world. However, their properties of heavier density, higher viscosity, and worse fluidity make them very difficult to produce and transport.

Recently, researchers from the Institute of Acoustics of the Chinese Academy of Sciences have investigated the ultrasonic wave technique to improve its rheological properties in the field of heavy crude oil and ultra heavy crude oil. An ultrasonic batch processing system with 4 ultrasonic horns whose basic frequency is 17 kHz is designed and installed in the Xinjiang oil field in the northwest of China. Pilots show that this system can be used to reduce the viscosity of ultra heavy crude oil for the practical production and transportation on the industrial scale.

In the lab, the viscosity of the emulsion of ultra heavy crude oil, water and viscosity reducer processed by ultrasonic wave has a more than 25% decrease of viscosity reduction, and 20% less quantity of active macromolecule viscosity reducer is needed.

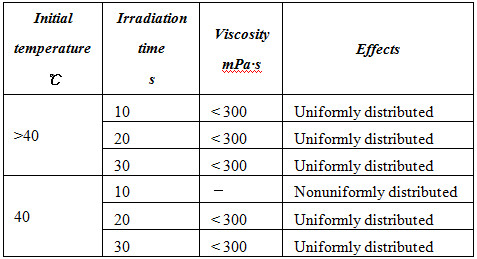

When the initial temperature is not lower than 40℃, the uniformly-distributed emulsion can form when it is subjected to 10-30s ultrasonic irradiation. The mechanisms of effects of high intensity ultrasonic wave on the viscosity reduction are emphatically investigated.

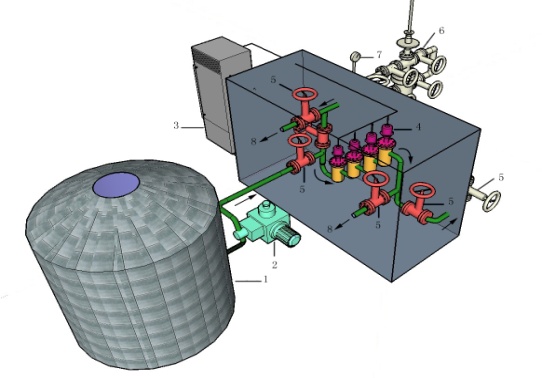

According to the experiments, an ultrasonic batch processing system with 4 ultrasonic horns whose basic frequency is 17 kHz is designed and installed in the Xinjiang oil field in the northwest of China (see Fig.1). Pilots show that this system can be used to reduce the viscosity of ultra heavy crude oil for the practical production and transportation on the industrial scale.

The obvious viscosity reduction effects of ultrasonic wave on heavy crude oil or ultra heavy crude oil can be observed for examples whose viscosity irradiated by ultrasonic wave is 25% lower than that un-irradiated at 20 centigrade, and 20% less quantity of active macromolecule viscosity reducer is needed. And the reason of the phenomenon observed is analyzed qualitatively.

The uniformly-distributed oil in water emulsion can form, when their miscible liquid is subjected to the 10-30s irradiation of ultrasonic wave emitted by the horn designed in this research (see Table 1).

According to the results in the oil field, the prototype of ultrasonic batch processing for the ultra heavy crude oil can be used to reduce the viscosity of ultra heavy crude oil on the industrial scale. And some improvements need to be made for the further practical industrial production.

The results obtained in this research can provide a solid foundation for the development of new ultrasonic technologies of reducing the viscosity of ultra heavy crude oil, which is helpful for improving and keeping good fluidity of heavy crude oil and ultra heavy crude oil during their extraction and pipe transportation.

Fig.1 Ultrasonic batch processing system for viscosity reduction (Image by XU)

Table 1 Effects of ultrasonic wave on Fengcheng ultra heavy crude oil in water emulsion distribution (Table by XU)

Reference:

XU Delong, DENG Jingjun, LIN Weijun, LI Chao, and BAI Lixin. Ultrasonic Batch Processing of Ultra Heavy Oil for Viscosity Reduction on the Industrial Scale. Ultrasonics Symposium (IUS), 2015 IEEE International, 21-24 October, Taipei, Taiwan. DOI:10.1109/ULTSYM.2015.0348

Contact:

XU Delong

Ultrasonic Technology Center, Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

Email: xudelong@mail.ioa.ac.cn