Perforated plates behind with fiber or porous materials are widely used in noise control engineering. The fiber or porous materials can greatly improve the sound absorbing performance of the perforated plates because they afforded additional damping for the construction.

However, this type of sound absorbing construction could not be utilized in many severe circumstances for special demand such as fireproofing, green environmental protection and so on. In 1974, Professor Maa Dah-You from the Institute of Acoustics (IOA) of the Chinese Academy of Sciences put forward a revolutionary idea that the sub-millimeter perforations of panels could provide sufficient acoustic resistance for a high absorbing coefficient in place of the fiber or porous materials .

At the same time, Maa founded the theory of the micro-perforated plate (MPP) and presented its engineering design. Although MPP sound absorber had a larger frequency band of absorption, it still did not fulfill some engineering requirements, especially in low frequency range.

Recently, several researchers from IOA have done a theoretical and experimental discussion on how to design a low frequency perforated panel sound absorber with short extended tubes in a limited thickness. The extended tubes have proved they can greatly shift the sound absorption peak to low frequencies.

Emphasis was focused on the low frequency range 100-300Hz and size limit 100mm in thickness. The theoretical model was also presented to predict the sound absorbing performance. Measurements in the impedance tube gave a good agreement with the predictions.

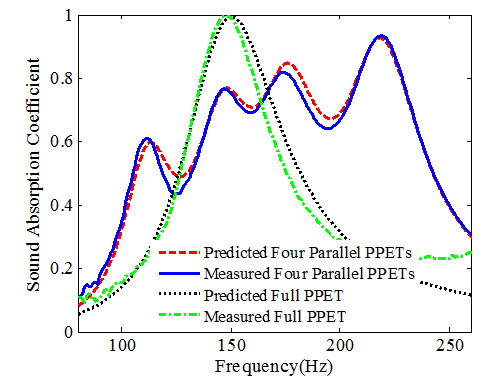

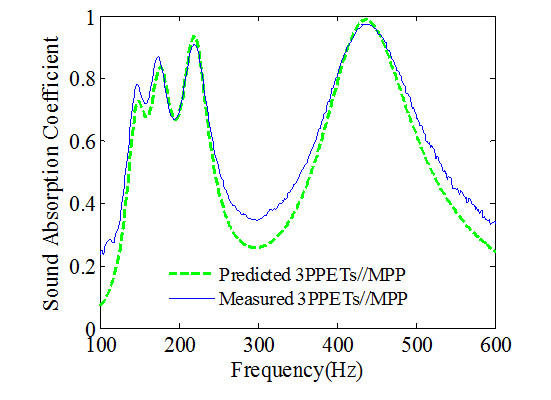

In order to widen the sound absorption frequency bandwidth, four parallel PPETs (perforated panel sound absorber with short extended tubes) and three PPETs compound with one MPP were also investigated.

Optimization of the cavity depths of the Four Parallel PPETs greatly increased the sound absorption bandwidth. The combination of the Three Parallel PPETs and one MPP also obtained a good sound absorption performance that could cover low and middle frequency range (100-600Hz).

The theoretical model was also presented to optimize the sound absorption performance of the PPETs. And the predicted results got a good agreement with the measurement in the impedance tube.

Funding for this research came from the National Basic Research Program of China (973 Program, 2012CB720204), and the National Natural Science Foundation of China (Grant No.11374326).

Fig.1 Prediction and Measurements of the sound absorption of Four Parallel PPETs (Image by CHANG).

Fig.2 Prediction and Measurements of the sound absorption of the three parallel PPETs // MPP (Image by CHANG).

References:

CHANG Daoqing, LI Dengke, LIU Bilong, TIAN Jing. A Perforated Panel Sound Absorber for Low Frequencies. Proceedings of the 22nd International Congress on Sound and Vibration, ISBN 978-88-88942-48-3/ISSN 2329-3675, The 22nd International Congress on Sound and Vibration (ICSV22), 2015.

Contact:

CHANG Daoqing

Key Laboratory of Noise and Vibration Research, Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

Email: changdq@mail.ioa.ac.cn