Keywords: Surface acoustic wave; Love wave; Humidity sensor; PVA; SU-8; Relative humidity

Surface acoustic wave (SAW) humidity sensor has many advantages, such as high sensitivity, wide detection band, and high frequency, so it is increasingly used in food storage and processing, weather forecast, medicine, etc. Polymer materials are commonly used as acoustic waveguide layer, and it is often adopted as sensitive films for SAW humidity sensor. Nevertheless, the insertion loss of this sensor will increase due to the polymer’s viscoelasticity.

Love wave (a kind of shear horizontal SAW) humidity sensor which has a suitable waveguide layer above the substrate and interdigital transducer (IDT) can get higher sensibility and lower insertion loss. As well, polymers are often adopted as guiding layers and sensitive films for Love wave sensors. However, few humidity experiment research of Love wave sensor with different polymeric layers structure had been reported.

Researchers from the Institute of Acoustics (IOA) of the Chinese Academy of Sciences have recently investigated humidity sensing by Love wave detectors coated with different polymeric films. An experimental investigation was performed to test and verify it.

In the experiment, the Love wave device consisted of two IDTs with a period of 28 μm, an ST-90˚X quartz substrate (Fig.1). Of polymer materials, since polymer waveguide (such as SU-8) had high sensitivity, low shear velocity, and relatively simple coating process; polyvinyl alcohol (PVA), a kind of commonly used polymer hygroscopic material had good hygroscopicity and was generally made by the spin coating method, they were used in this experiment.

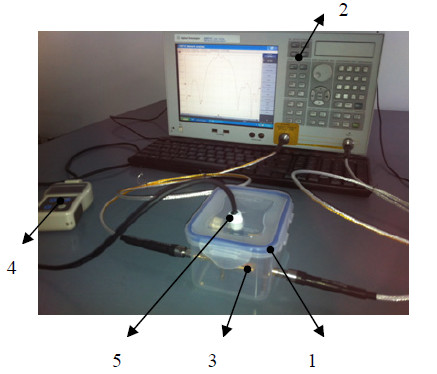

Three different films of SU-8, SU-8+PVA and PVA, were spin-coated on the substrate surface as the waveguide layer and the sensitive film. A detailed description was presented for the preparation of the solution and coating and curing process of SU-8 and PVA. And a network analyzer (Fig.2) was used to measure the operation frequency and insertion loss of the sensor at different relative humidity (RH).

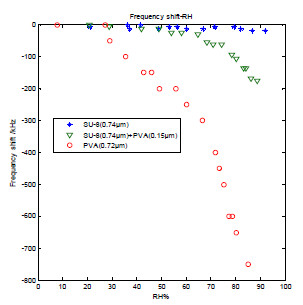

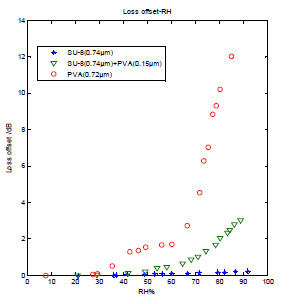

Fig.3 and Fig.4 showed the relationship between frequency offset (loss offset) and RH, indicating Love wave humidity sensor coated with PVA film was the best. The frequency offset of device coated PVA film was largest and loss offset was acceptable. Besides, the absorption mechanism of polymeric layers was analyzed and the mechanism was successfully used to explain the experimental results of the humidity sensing of Love wave devices coated with SU-8, SU-8+PVA, or PVA layers.

Fig.1. Delay line structure of Love wave humidity sensor (Image by IOA)

Fig.2. Experimental facility (1) Seal box, (2) network analyzer, (3) Love wave device, (4) hygrometer, (5) hygrometer probe (Image by IOA)

Fig.3. Frequency offset - Relative humidity (Image by IOA)

Fig.4. Loss offset - Relative humidity (Image by IOA)

References:

WANG Lijun, LIU Jiansheng, HE Shitang. Humidity Sensing by Love Wave Detectors Coated with Different Polymeric Films. Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), 2014 Symposium on, ISBN 978-1-4799-6424-6, IEEE (pp. 44-47, Oct. 30 2014-Nov. 2, 2014, Beijing, China). DOI: 10.1109/SPAWDA.2014.6998522

Contact:

LIU Jiansheng

Institute of Acoustics, Chinese Academy of Sciences, 100190 Beijing, China

E-mail: liujs98@hotmail.com or liujiansheng@mail.ioa.ac.cn