Cavitation is a specific liquid dynamic phenomenon that usually occurs during the operation of hydraulic machinery. This phenomenon is a subject of great concern because it reduces mechanical efficiency, degrades and damages the surface of the propeller, and increases undesirable vibrations and noise emissions. These factors affect the service life and operational safety of hydraulic equipment.

Researchers from the Institute of Acoustics, Chinese Academy of Sciences and the Beijing University of Posts and Telecommunications have proposed a novel method for detecting cavitation with phase demodulation of ultrasonic signals.

The ultrasonic propagating in a flow field is modulated by the transient fluid velocity information, so that the continuous demodulation of the received signal enables the measurement of the flow field velocity pulsation. And the relationship between the demodulated signal and the spatial mean value, which is the particle velocity component in the direction of the ultrasonic signal along the path of ultrasonic propagation, is established.

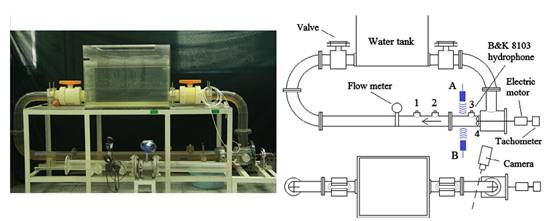

Moreover, the modulating signal is recovered by following baseband signal processing. The effect of liquid cavitation on the ultrasonic propagation velocity is verified by the experimental study (see Fig. 1). The power of the demodulated signal, being almost zero when the fluid is still, increases clearly along with fluid motion.

Fig. 1 Image and schematic diagram of the closed-loop system for the cavitation experiment. The ultrasonic transducers are located at points A and B. The B&K 8103 hydrophone can be installed at points 1, 2, or 3 for cavitation detection. Point 4 is the axial flow pump impeller (Image by YAN).

Furthermore, a sudden increment in the power and pulse characteristics appears during cavitation inception. The accuracy of the proposed cavitation recognition method is over 98%, which is comparable to the performance of the acoustic method using a hydrophone. In addition, the ultrasonic transducers in the proposed method are easy to be installed on the outer surface of the pipeline. This nonintrusive installation method is more convenient than the installation methods that use pressure and hydroacoustic signal analysis in some engineering applications.

For future research, this method can also be used for the identification of laminar and turbulent flows, especially in nontransparent fluids.

References:

YAN Zhaoli, LIU Jin, CHEN Bin, CHENG Xiaobin, YANG Jun. Fluid Cavitation Detection Method with Phase Demodulation of Ultrasonic Signal. Applied Acoustics (vol.87, pp. 198–204, January 2015).DOI: 10.1016/j.apacoust.2014.07.007

Contact:

YAN Zhaoli

Key Laboratory of Noise and Vibration Research, Institute of Acoustics, Chinese Academy of Sciences, Beijing 100190, China

Email: zl_yan@mail.ioa.ac.cn