In the past couple of decades, ultrasonics has obtained wildespread applications in industry, such as in non destructive test, medical diagnosis, high intensity focused ultrasound, nano technologies, waste water treatment and so on. Nowadays, such applications have extended to the branches called sonics, sonochemistry, sonoluminescence et al. The mechanism of these applications can be attributed to the acoustic cavitaton, a “magic” phenomenon which induces extreme conditions such as high temperature and high pressure, high density and highly intense shock waves resulting from the collapse of the transient cavitaion bubbles.

However, up to now, the aforementioned successful processing applications of ultrasound based on cavitation mechanism are mainly confined to the laboratories. The major shortcoming of ultrasound reactors that have contributed mostly to their poor performance on an industrial scale operation is that cavitation occurs only in the close vicinity of the surface of the sonicator. Consequently, it severely limits the volume of the active part of the reactor.

Researchers from the Institute of Acoustics, Chinese Academy of Sciences have investigated to optimize the spatial distribution of cavitation in a dual source sonoreactor. In this research, firstly, the “point” (small area) cavitation measuring methods-hydrophone method, iodine releasing mehtod (RIM) and aluminum foil erosion method are proposed, adopted and improved. The reason why the “point” method is emphasized is that it is the prerequisite of spatial distribution control and optimization of cavitation. To control the spatial distribution of cavitation better, the cavitation must be produced accurately in the position that it is needed.

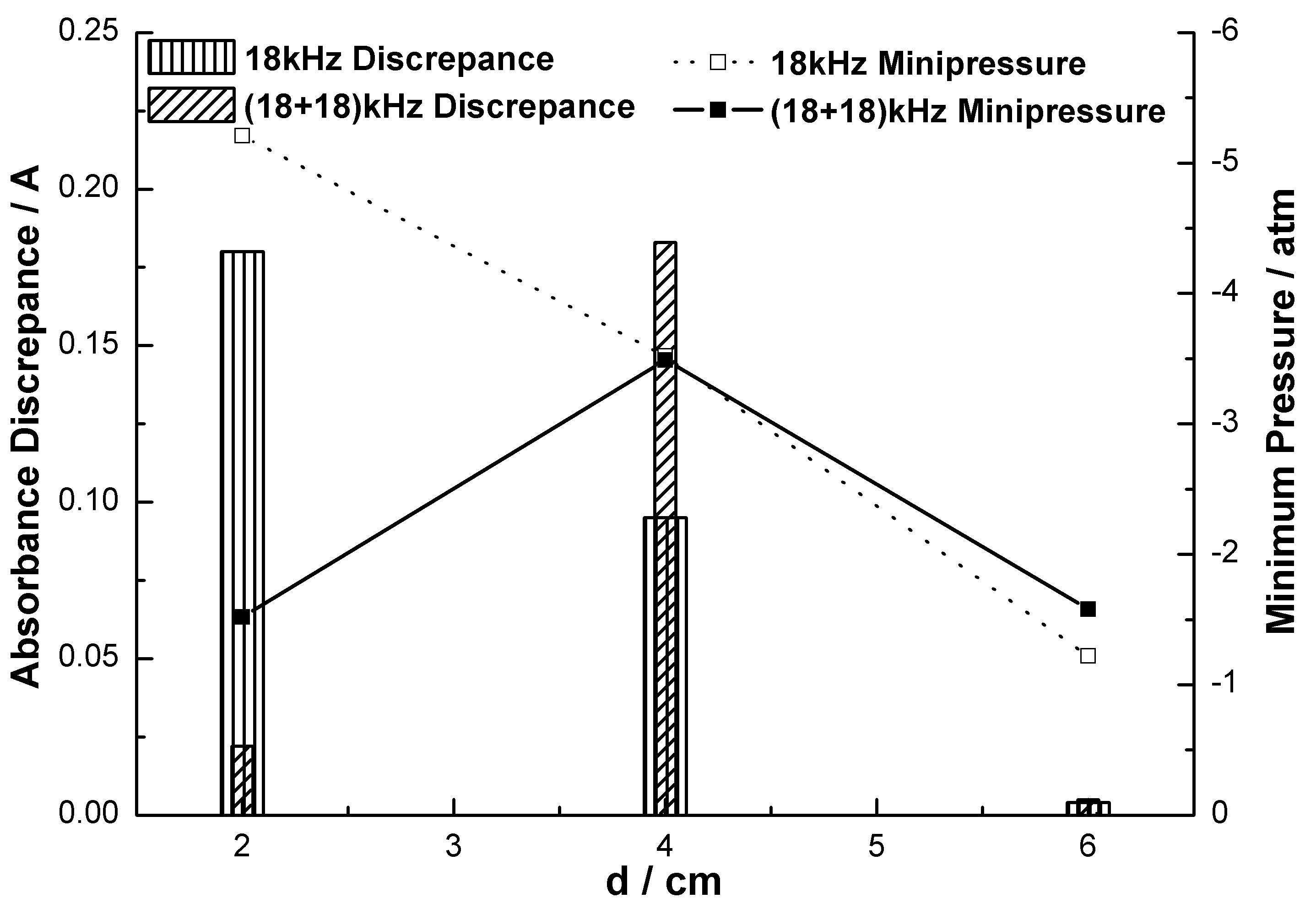

According to the experiments, more cavitations have been successfully produced in the middle space of the two transducers. Whereas, in the vicinity of the transducer, its occurrence is lesser and negligible (See Fig.1). This is very important because it makes possible for us to produce cavitations in wider area and increase the total power input. The improvements will make the optimization of cavitation spatial control more feasible in industry scale.

Fig.1 Comparison of mono and dual source in sonoreatctor for RIM and hydrophone method

(18kHz : mono source (18+18)kHz : dual source) (Image by XU).

References:

XU Delong,DENG Jingjun,CHAO Li and BAI Lixin.Optimization Control of Cavitation Spatial Distribution in a Dual Source Sonoreactor.Proceedings of the 21st International Congress on Sound and Vibration, ISSN2329-3675/ISBN 978-83-62652-66-2, International Institute of Acoustics and Vibration (IIAV), SS24-27, 2014.

Contact:

XU Delong

Laboratory of Ultrasonic Physics and Exploration, Institute of Acoustics, Chinese Academy of Sciences, Beijing 100190, China

E-mail: xudelong@mail.ioa.ac.cn