In the first decade of the 21st century, the global demand for crude oil had a remarkable yearly growth rate from 1% to 1.8% (International Energy Agency, 2009). According to its statistics, heavy crude oil and high pour point crude oil (HPPCO) represents more than 50% of the world’s recoverable oil resources. Therefore, HPPCO reservoirs are getting more and more attentions in the world because of global energy demand and high price of crude oil. However, more difficulties are faced for the extraction of HPPCO due to its higher pour point (PP) and worse fluidity, especially when the temperature is low.

Traditional methods to solve the problem are heating, injecting light crude oil or hydrocarbon or adding pour point depressant (PPD). Heating consumes more energy during transportation. And injecting light crude oil can lead to wax deposition because co-mingling of two or more oil, neither of which have paraffin problems when produced separately, may cause the precipitation of waxes. The effects of adding pour point depressant is dependent on the conditions of each field climate and oil composition, among others. Up to now, there is no PPD can be used for the HPPCO whose properties are different.

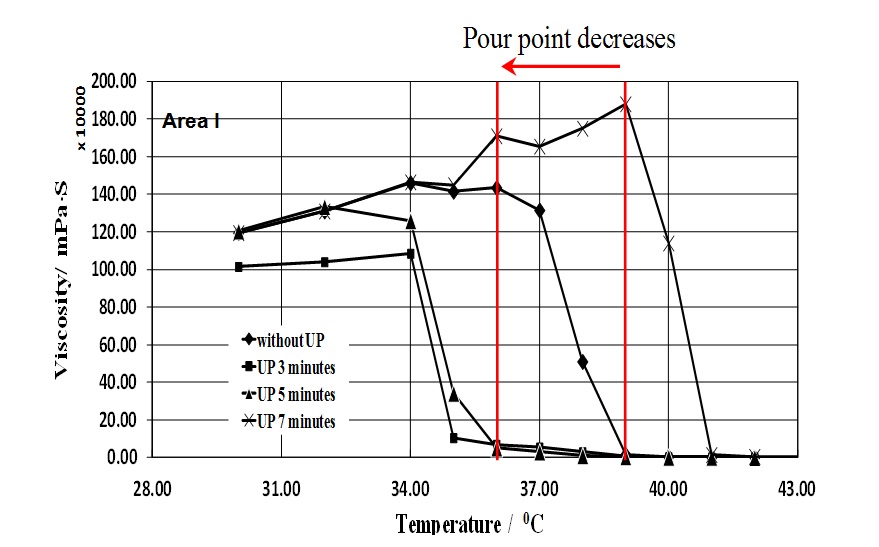

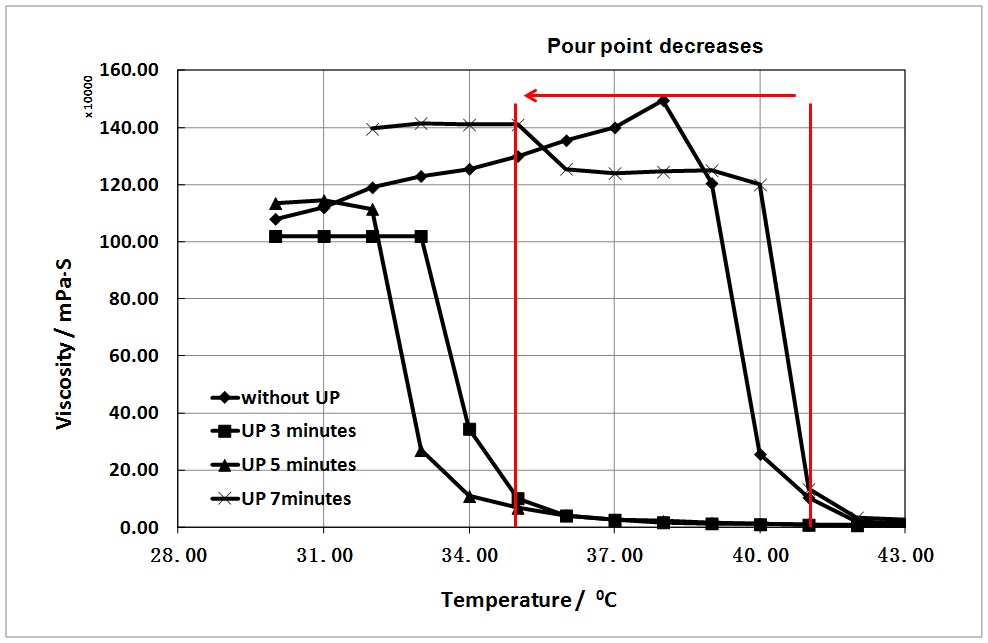

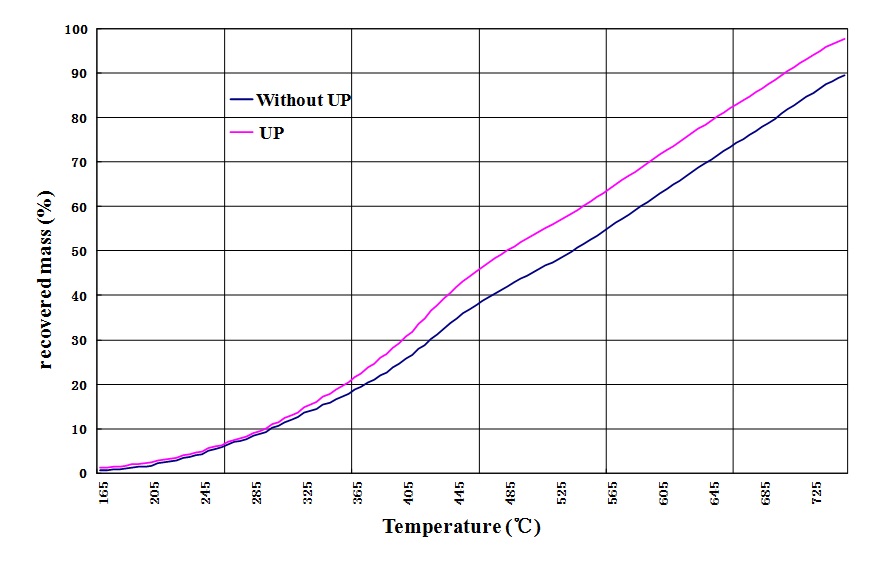

Researchers from the Institute of Acoustics, Chinese Academy of Sciences investigate a method to solve this problem. Ultrasonic processing (UP) can be used to improve rheological properties of crude oil. After using UP, the PP of Area I HPPCO decreases 3℃ when the UP time is 3 and 5minutes respectively (See Fig.1). As well, for Area II HPPCO, a decrease of 6℃ is obtained (see Fig.2). The recovered mass fraction for Area I HPPCO rises from 89.5% to 97.8%. For Area II, there is no obvious change before and after UP (see Fig.3 left).

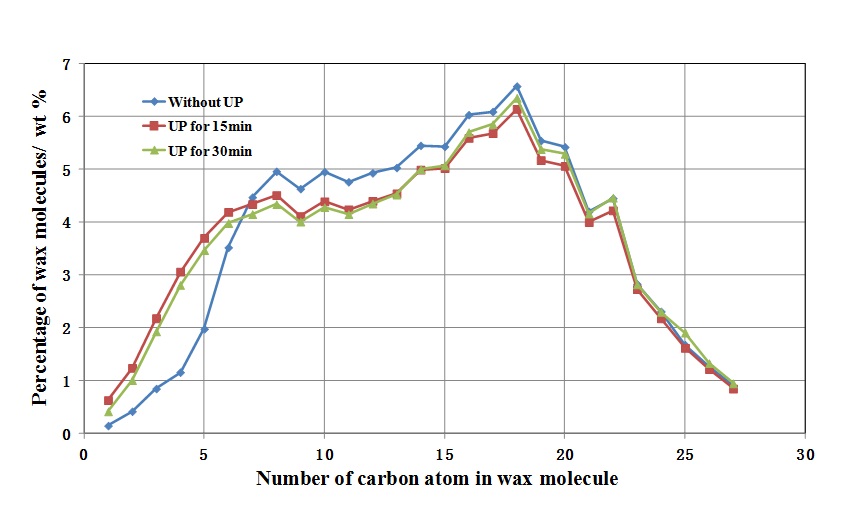

By using UP, the percentage of wax molecules with 10-15 carbon atoms increases 320%, 195%, 156%, 163% and 87%. Meanwhile, that with 18-22 carbon atoms decreases 11.2%, 11.3%, 10.9%, 10.8% and 9.7%. Compared with no UP, the percentage of higher molecular weight constituents becomes more, while that of heavier molecular weight component is less (see Fig.3 right).

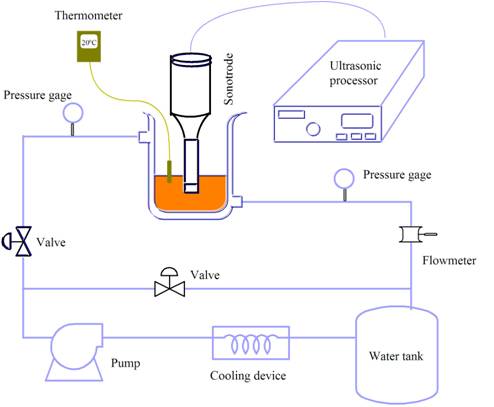

Fig.1 Setup for improveing PP and properties of HPPCO (Image by XU)

Fig.2 Effects of ultrasonic wave on PP of HPPCO (Image by XU)

Fig.3 Effects of ultrasonic wave on recovered mass (left) and wax component (right) of HPPCO (Image by XU)

References :

XU Delong, DENG Jingjun, LI Chao, BAI Lixin and SHAO Beili. Effects of Ultrasonic Wave on the Pour Point and Properties of Sudan High Pour Point Crude Oil. The 14th Meeting of the European Society of Sonochemistry (ESS14) (June 2-6th, Avignon University, France) . http://ess14.univ-avignon.fr/

Corresponding Author:

XU Delong

Laboratory of Ultrasonic Physics and Exploration, Institute of Acoustics, Chinese Academy of Sciences, Beijing 100190, China

E-mail: xudelong@mail.ioa.ac.cn