The rapid development of desiccant air conditioning technology, which can handle sensible and latent heat loads independently, has expanded desiccant industry to a broader application. Compared to liquid desiccants, solid desiccants are non-corrosive and have drawn more attention. The desiccants require considerable heat to be regenerated to work repeatedly after saturated with moisture. However, due to the releasing of adsorption heat in dynamic adsorbing process, dehumidification process occurring in solid desiccant is away from the ideal isothermal dehumidification process. Besides, the required regeneration temperature is higher which will impact the utilization of the low grade heat source such as waste heat rejected by energy conversion devices and solar energy.

It has been highlighted in many research papers to improve the performance of desiccant system at a lower regeneration temperature. However, the effects of these studies resulted in being unsatisfactory. Later, some researchers had first studied the possibility of applying ultrasound in the regeneration of silica gel, which proved to be effective.

In this research, the regeneration of a new honeycombed desiccant material of different types assisted by ultrasound under different drying air conditions (temperature, velocity and humidity) are investigated experimentally.

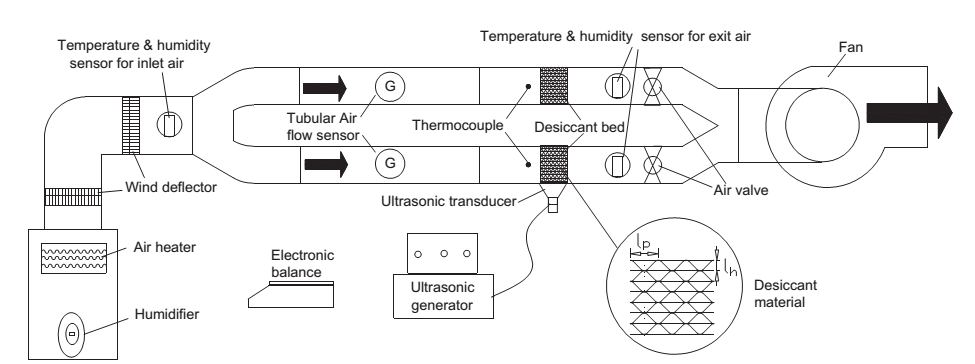

The schematic diagram of experimental system is presented in Fig. 1. As known from Fig. 1, the experiments of regeneration with and without ultrasonic radiation can be performed simultaneously.

Fig. 1 Schematic diagram for the experimental system (Image by YANG).

The biggest benefit for the design of the experimental system is that the airflow rate and the air conditions before the two desiccant beds can be easily kept the same. In addition, the distance between the T-bend of duct and the airflow sensor is long enough to guarantee a uniform airflow passing through the airflow sensor to improve measurement precision.

Three indexes, ERR (Enhancement Ratios of Regeneration), ERARR (Enhancement Ratios of Average Regeneration Rate) and AEE (Average Electricity utilization Efficiency), are used to evaluate the enhancement effect and energy-saving characteristic of using ultrasonic. The experimental results show that the enhancement effect of ultrasound on the regeneration is greatly influenced by material structural parameters and regeneration conditions. It increases with the airflow rate (increasing from 0.5 m/s to 0.9 m/s), and decreases with the drying air humidity (increasing from 0.008 to 0.012 kg/(kg dry air)). The drying air temperature has little effects on the ERARR. The AEE decreases with the regeneration air temperature, humidity ratio and velocity. Besides, applying ultrasound to the regeneration of M-type material is more effective. Furthermore, the contributions of ‘heating effect’ and ‘micro-vibration effect’ induced by power ultrasonic are discussed and the results show the contributions of the micro-vibration effect dominate. Meanwhile, a model is developed to predict the regeneration rate of the new desiccant material assisted by ultrasound.

This research with the title of “Investigation on Applying Ultrasonic to the Regeneration of a New Honeycomb Desiccant” has been published online: http://www.sciencedirect.com/science/article/pii/S1290072913001178 and on International Journal of Thermal Sciences (Volume72, pp159-171, 17 October 2013).