Sound imaging instrument, invented by YANG Yichun from IACAS is designed for detecting and measuring sound field. It exceeds foreign similar products for its advanced technology properties.

The Sound imaging instrument is not only used in the domestic market, but also has a very good reputation abroad. The University of Manchester, UK used to adopt this instrument for scientific researches.

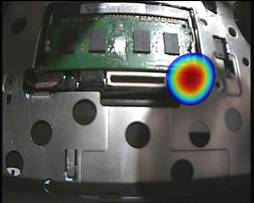

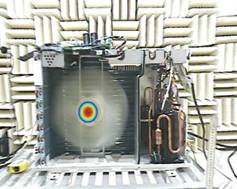

The Sound imaging instrument, commonly called Acoustic Camera, can display sound field as an image, which can show position and shape of the sound field visually.

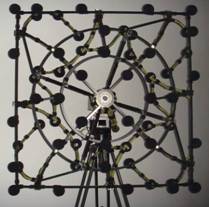

A series of Sound imaging instruments were developed by IACAS: the first kind is the one with 64 units plane spiral microphone array whose pixel of acoustic image is 418,000. It has several work patterns and 3 specifications of 1m, 2m and 3m based on its diameter. Its frequency range separating sound and image is 200Hz-6 kHz, and frame rate is 4fps-25fps. All of these major indicators have already exceeded foreign similar products’ standard. The second kind is the spherical Sound imaging instrument combined with 1/2 inch electrets-condenser microphones and specially designed micro preamplifiers. This combination can largely prevent sound fields from disturbance caused by array elements. Meanwhile, signals detection circuit on the array has good electromagnetic compatibility even working in the electromagnetic environment. In addition, Sound imaging instruments have advantages of compact structure and easy operation.

After the Sound imaging instruments were produced successfully, a mass of tests were carried out to trace the abnormal noise source. The Daya Bay nuclear plant, Foxconn, Huawei, ZTE telecom, China South locomotive & Rolling Stock Corp. and dozens of other grand enterprise had already used this instrument to diagnose their mechanical failures, especially the abnormal whistling noise of an auto production line.

Internally, there is no product paralleled with the Sound imaging instrument. Externally, comparing with products of Acoustic Camera (GFal, Germany), BBM (Germany), B&K (Demark), LMS (Belgium), ACB (France), Norsonic (Norway), the prominent features of the Sound imaging instrument are as follows. The instrument can optimize design of array distribution for better false image suppression capability and develop on the basis of actual application environment for working on complex sound field environment. It uses highest precision measurement microphone and micro preamplifier for measuring mechanical noise, while the foreign products are not suiting to mechanical noise because of their using of ordinary microphone. Larger aperture for measuring mechanical low frequency noise is equipped, while normal apertures of foreign products sold in domestic market are less than 1m. Large number of array elements (64 microphones) for strong noise suppression is provided, while some foreign products are 36 or 48 elements. It has high SNR of 14 dB for more and more accuracy acoustic image and broad frequency range of measurement of 2Hz-20kHz. The frequency range separating sound and image is 200Hz-6 kHz, while respective indicators of foreign products are 100Hz-10kHz and 600Hz-6000Hz. Dynamic range is 15dB-120dB and frame rate is 25fps, which is far more than foreign similar products. It could measure in-vehicles in multiple modes. The 4w power consumption can be supported by batteries for convenient operation. Only one USB connection between the Sound imaging instrument and computer is used, while foreign products need more complex electric connection.

Sound imaging instrument has been paid attention to by many industries and institutes since it came out, and was purchased by many universities and colleges for their research work in laboratory.

After a three-years market surveying and testing, it is proved that the Sound imaging instrument as a non-contacting noise measurement instrument can be widely applied not only for measuring and analyzing equipments’ noises, but also for evaluating and monitoring environment noises or detecting noise stimulated by vibration and other reasons. Sound imaging instrument can help to decrease noise in research and production of new equipments, locate the abnormal noise in equipments’ maintenance, evaluate the location and intensity of noise, observe status of generation and transition of multi-noise source, and examine status of equipment installation, debugging and running. It can also be applied in finding noises and failure of equipments in the manufacture and maintenance of household appliances, computer and communication products, as well as in the fields of manufacture, installation and running of auto, train, aircraft and ship, and manufacture of engines (petrol, diesel and electricity) and power generator (thermal, hydropower and wind).

Acoustic fault diagnosis technologies have made great achievements with appearance of the Sound imaging instruments which must have a very bright prospect and will push forward mechanical equipment fault diagnosis for a greater progress.